It all began 60 years ago with a clear concept: To develop and produce the most flexible machines for document handling. What followed were the first automated IT-controlled cutting machines, inserters and a wide range of products within our unique modular system. From the beginning we develop and produce almost all of our components from mechanics to electronics up to software under one roof – that you will always get the paper management system you need. Now and in the future.

The portfolio of Müller comprises eight product segments from applying cards to inserting up to the verification of documents. State-of-the-art technology and high reliability for a wide variety of requirements within pinfeed or pinless processing, whatever the paper format is: single sheet, stack, role or online from the printer. Numerous options, which can be expanded also to systems of other suppliers, allow a nearly limitless spectrum of applications.

Highest flexibility. Today and tomorrow.

From more than 100 combinable modules, we create the appropriate paper management system according to all of your requirements. Our modules are not only combinable with each other, but also match with existing systems with ease. You want to carry out a new product idea in a very short period of time? Fine, the modular components can be swapped out and changed easily. Lettershops become output centers for statements with extensive documentation. Capacity utilization of CRDs is assured by additional direct mail. Prepare yourself for the future today.

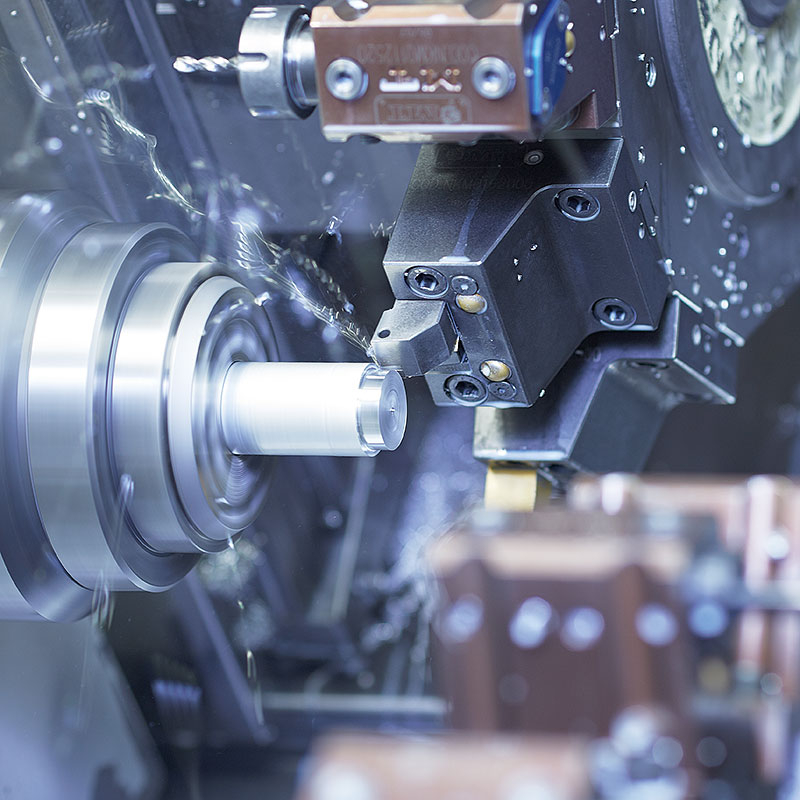

Made in Germany. We remain true to this quality. From the mechanics and electronics to the software we produce consistently in our own country and to the highest German quality standards. This means: Maximum precision thanks to well-trained professionals, state-of-the-art equipment and quality materials. Thus we spare you unnecessary downtime and increase your productivity. This is also highly appreciated by our many international customers.

Process

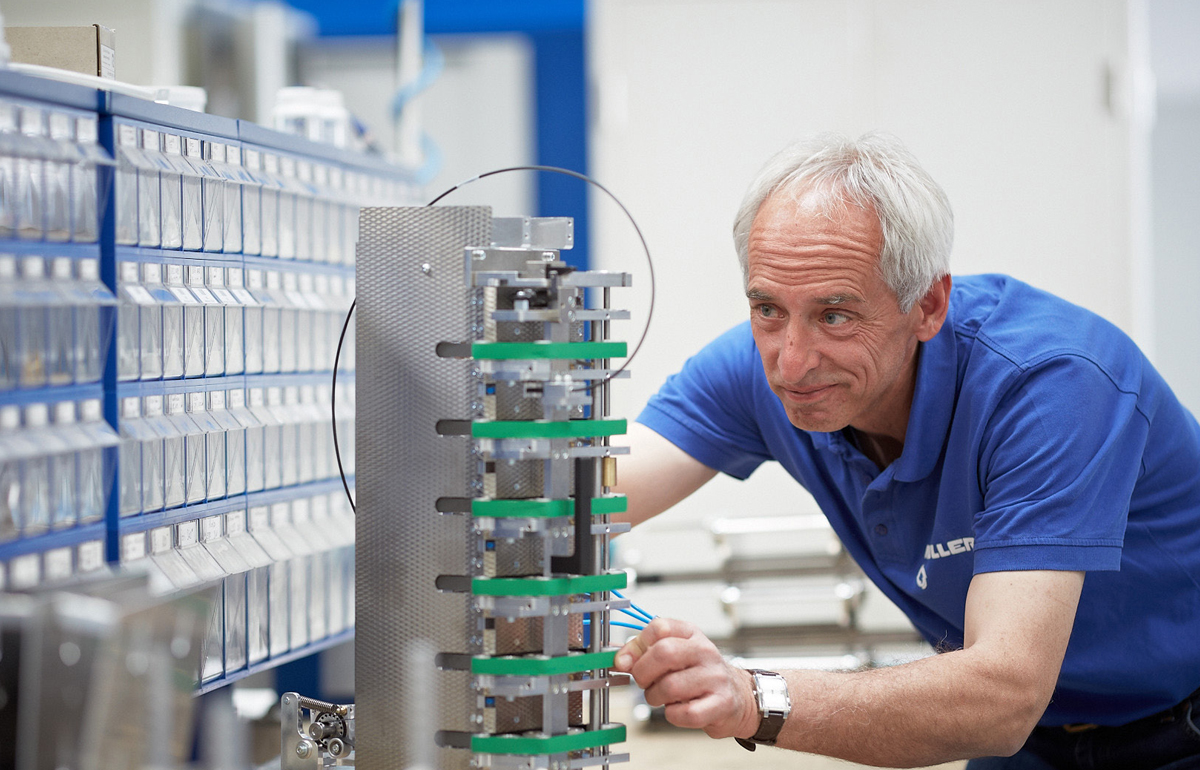

Our quality process comprises a multi-level procedure up to the testing of the whole system. The custom-tailored system is put to the acid test with the client’s application. Single parameters will be customized, such as the adjustment of sensors and the positioning of cameras. The final step in the quality process also includes the acceptance test with our clients.

Sustainable development

Only resource-efficient management is sustainable. All our systems are designed for durability. High-quality materials, repairable and maintainable individual parts, and the intelligent overall design of our systems enable smooth and flexible use over the long term. If your production processes change, the modular nature of our systems means that only individual components need to be replaced, rather than entire systems.

Müller. Simply independent. Since the beginning of the company’s history, Müller has one objective: To be as independent as possible from suppliers in the production of paper management systems. Key elements for this independence are our own software solutions and the in-house production of most items, boards and wire harnesses. This not only speeds up the development of the systems. At any time we can produce spare parts and so our systems can stay in operation for decades.

The company continues to grow and we are always looking for suitable staff: young professionals and professionals, full-time and part-time workers, craftsmen, engineers, technicians, administrative staff. Find out about our job vacancies! By the way: We also train. 60 years of experience in the development and production of paper management systems - this know-how, we are happy to share.

Our goal is to ensure the consistently high quality of our products, processes and services. To this end, we are constantly working to improve and further develop our quality management system. Following a successful audit by EQM ZERT, Müller's quality management has now been recertified in accordance with ISO 9001.

Every year, the global company EcoVadis recognizes companies for their commitment to sustainability. This year, Müller Apparatebau underwent EcoVadis' renowned sustainability rating for the first time and achieved an excellent score of 59 out of 100 points. This was rewarded with a bronze medal from the renowned rating agency. This means that Müller is among the top 35 percent of all companies worldwide with a valid EcoVadis certificate.

The following terms and conditions apply to all business transactions between Müller Apparatebau GmbH (Müller) and the customer (Buyer) even if they are not mentioned in subsequent contracts. The following terms and conditions also apply to agreed services, such as service and maintenance work (services).